Agile and Lean

A buddy of mine from college, Brady Beckham, recently got in touch with me to ask me about agile. He’s a continuous improvement (CI) manager at EFCO Corpration, a company that manufactures windows. He focuses on lean manufacturing, trying to identify and eliminate or reduce waste in the manufacturing process. Through this, he had stumbled across agile and got enough of a sense of it to realize that there was probably some overlap. He gave me a call and asked if we could get together and share knowledge. Naturally, I jumped on that opportunity.

A few of my Shelter coworkers and I drove down to his factory in Monett, Missouri for a two-day knowledge transfer session. We toured the factory so that we would have a common understanding as we talked through lean concepts. We participated in a Lego simulation that illustrated some of those concepts. We gave them a very rough overview of agile. We kind of blew our agenda after that. It’s not surprising since our agenda was set with a bunch of unknowns. Still, the resultant conversations were illuminating.

Lean and Agile in Production and Support

One of the most interesting things we noted, from my perspective, was the relationship of lean and agile to support and production. At EFCO, production means making windows. Support is the CI group. We quickly realized that while lean was clearly the better process improvement and project management approach for their production process, agile might be better for that support process. I drew the analogy that agile is applicable when the end product isn’t known. Since the CI group’s end product is a “perfect factory,” and no one knows that that actually means, agile might be the way to get there.

Contrast that with software development. In this case, the software development process is the production line. Support is more like building and maintaining development machines, networks, etc. These are repeatable processes with a defined end product. This is where lean excels.

This leads me to wonder if that similar, inverse correlation would be found elsewhere. It’s only been a couple of days since our visit, but I’ll be watching out for arenas where there is a main function and a support function, and trying to match up whether I think agile or lean ideas will be more applicable to one or the other.

As a side note, I’ve searched around for “lean IT” and found out it’s a thing. However, no one seems to make the connection between support and development. In fact, some authors seem to think it’s a way to bridge the two, but don’t give much in the way of supporting arguments. Who knows? Maybe I’m way off.

A Natural Pull System

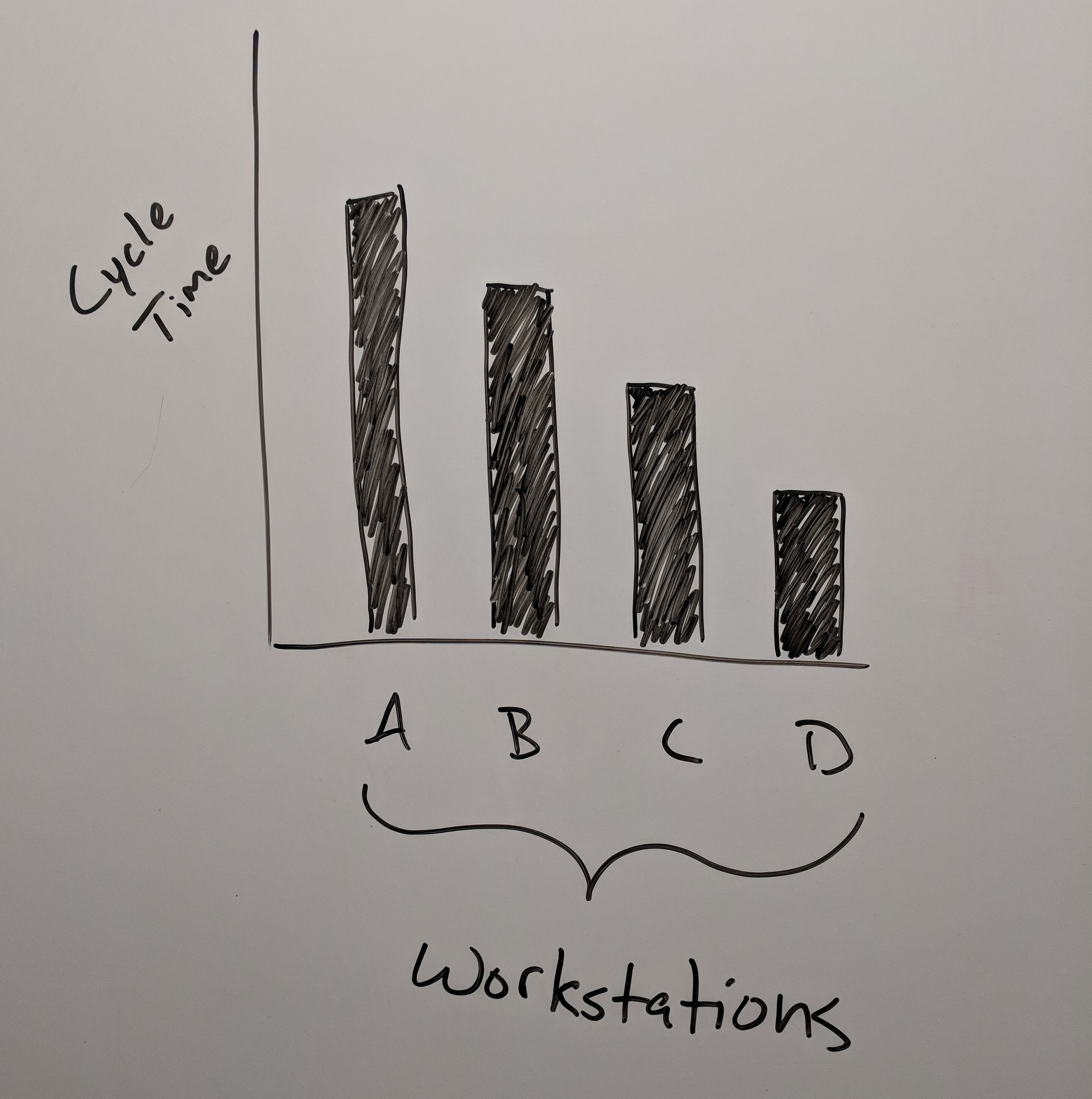

Another thing that I thought was really interesting was that Brady showed us a picture that illustrated a natural pull system.

The successively shorter cycle times should lead to each workstation finishing their work slightly faster than the station before, creating a pull system. This is one of those simple truths that is super obvious once you see it, but had never occurred to me before.

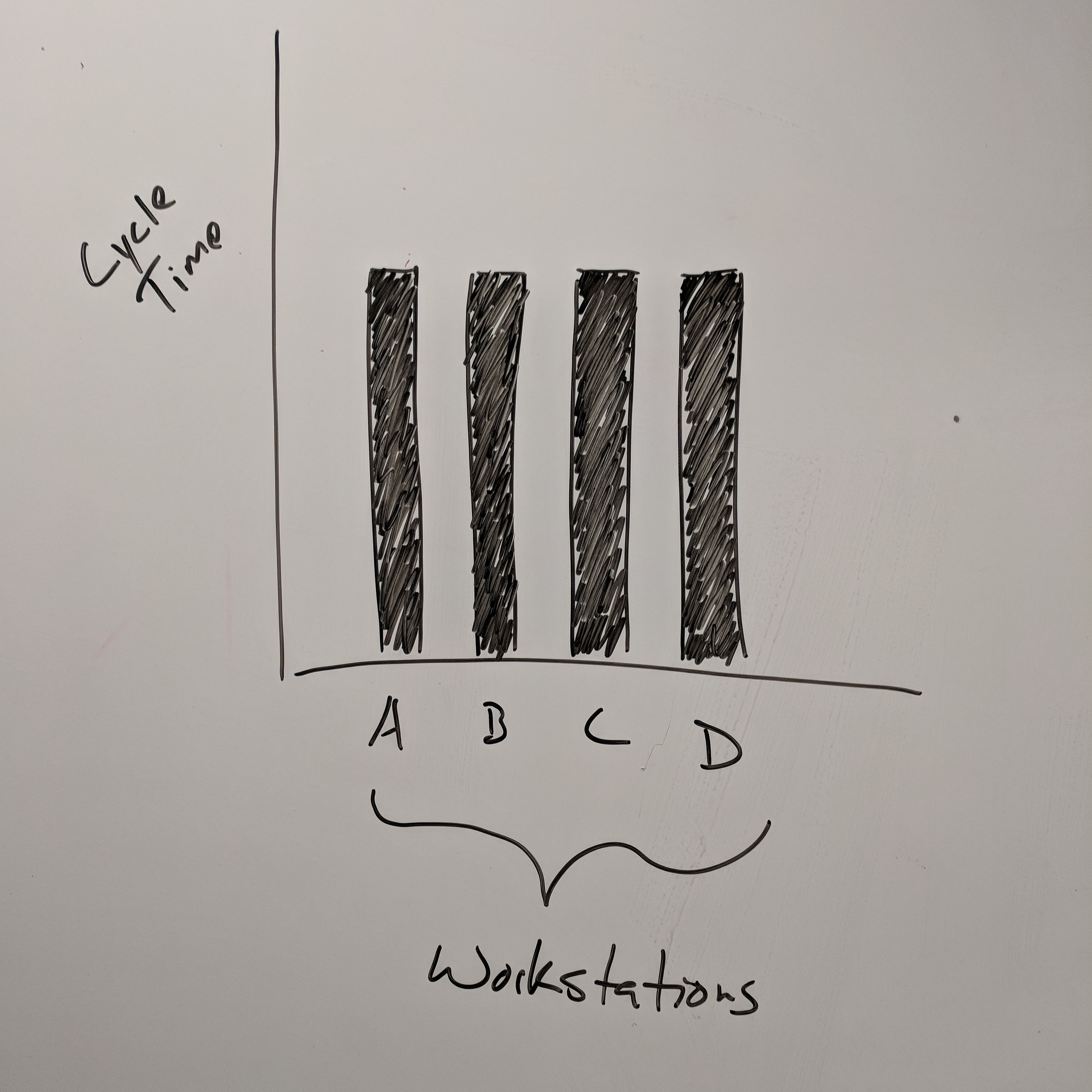

What I found equally interesting, but seemed like too deep a rabbit hole to go down at the moment, was that Brady next showed us what is generally advocated for in lean.

Balancing the cycle times of your workstations seems like one of those things that would be desirable at face value, but no longer once you dig a little below the surface. I was surprised to find that the lean community hadn’t moved away from this, much the way that the agile community has moved away from the waterfall-style planning that makes sense until you examine it a bit. It’s definitely something I’ll have to dig into a bit more to understand.

Those were my two big takeaways, but there were a lot of other conversations about lean and agile that I found useful. We talked about kaizen events, saw an agenda for one, looked at some kanbans in the manufacturing context, saw some common lean tools, and a whole lot more. I think it was a little lopsided in that we got more our of it than they did. In the future, I’m hopeful that Brady and his coworkers can come to one of our agile training events so we can return the favor.